Within the framework of the ePARADISE project, supported by ADEME and the Pays de la Loire region, VALEMO is working in partnership with the LHEEA (Laboratory in Hydrodynamics, Energetics and Atmospheric Environment, attached to the Ecole Centrale de Nantes), the CSTB (Centre Scientifique et Technique du Bâtiment) and Mer Agitée (Michel Desjoyeaux’s offshore racing team).

The project consists in optimising two types of aerodynamic sensors for wind turbines in operation. The sensors in question are the ePenon, developed by Mer Agitée, and wireless pressure sensors installed by CSTB.

The use of these sensors will eventually optimise electricity production by detecting nacelle misalignment or blade misalignment and consequently improve the life of a wind turbine and possibly reduce its noise emission. Over the past 18 months, several milestones have been reached.

VALOREM’s (VALEMO’s headquarter) wind studies office has installed a wind measurement mast in October 2020 in order to characterise the upstream wind and VALEMO will install a nacelle Lidar in order to characterise the nacelle misalignment. The data obtained will be used to characterise certain turbine operating points in relation to the operation of the ePenons and will be coupled with acoustic measurements.

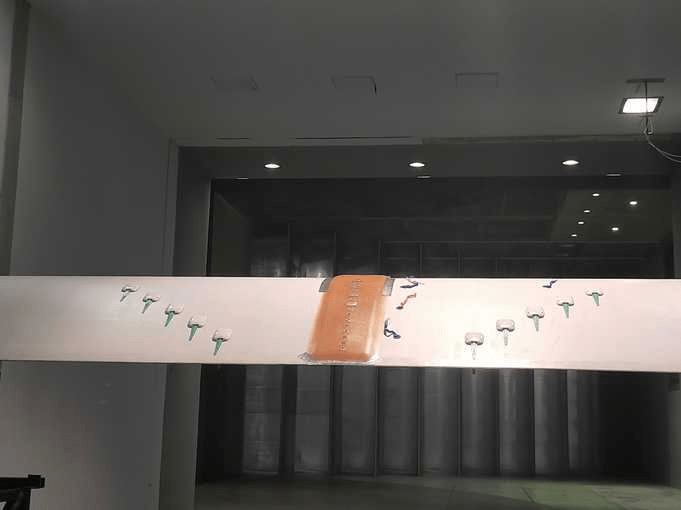

The wind turbine blade concerned by the installation of the sensors was scanned on site and reproduced in a wind tunnel, at scale 1 in the CSTB wind tunnel and at reduced scale in the LHEEA wind tunnel. A first series of scale 1 tests were carried out in November 2020 and allowed to validate the operation and the installation of the sensors as well as to determine the most relevant locations of these on the blade. The originality of the experimental installations used is that they can reproduce wind gusts.

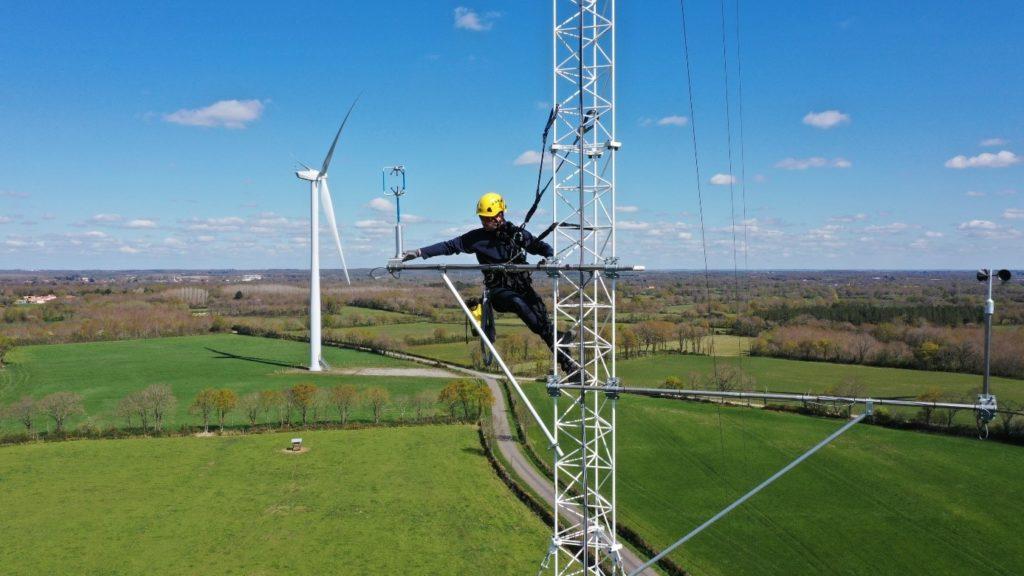

At the beginning of April 2021, ePenons sensors were installed on a wind turbine of the Saint-Hilaire de Chaléons wind farm, operated by VALEMO and belonging to VALOREM. 8 sensors were glued on each blade.

The next steps of the project will be to force wrong settings on the wind turbine (yaw angle, pitch angle) during a short test phase and to analyse the response of the ePenons sensors and their ability to detect these wrong settings.